The PowerFlex 700S is a high-performance AC drive designed for versatile applications. This manual provides essential guidance for qualified personnel regarding programming and operation.

Understanding parameter settings and functions is crucial for effective PowerFlex 700 utilization, encompassing drive, PowerFlex 700, or PowerFlex 700 Drive configurations.

Recent updates, like those in Vector Control Firmware 4.001, have refined the manual, with certifications and specifications now found in separate technical data publications.

What is the PowerFlex 700S?

The PowerFlex 700S represents a robust and adaptable high-performance AC drive solution, engineered for a broad spectrum of industrial applications. It’s frequently referenced simply as the “drive” or “PowerFlex 700 Drive”. This drive utilizes advanced control techniques, including Phase II Control, to optimize motor performance and efficiency.

It’s designed for qualified personnel capable of programming and operating adjustable frequency AC drive devices. The PowerFlex 700S offers versatile control, requiring a solid understanding of its parameter settings and functions for optimal implementation. It’s a key component in modern automation systems.

Target Audience for this Manual

This comprehensive manual is specifically crafted for qualified personnel involved in the installation, programming, operation, and maintenance of the PowerFlex 700S AC drives. Individuals should possess a foundational understanding of adjustable frequency AC drive technology and associated safety procedures.

The intended audience includes commissioning engineers, maintenance technicians, and automation specialists responsible for integrating and troubleshooting drive systems. A working knowledge of electrical systems and motor control principles is essential for effectively utilizing the information presented within this document.

Document Revision History

This manual undergoes periodic revisions to reflect product updates, enhancements, and user feedback. The PowerFlex 700 AC Drives Frames 010 manual, specifically with Vector Control Firmware 4.001 and later, has seen changes since its last release.

Notably, product certifications and detailed specifications have been relocated from this manual to the PowerFlex 700 Adjustable Frequency AC Drive Technical Data publication (20B-). Users should always reference the latest documentation available online or through Rockwell Automation resources.

Safety Precautions

Qualified personnel must adhere to general, electrical, and mechanical safety guidelines when installing and operating the PowerFlex 700S drive.

Always prioritize safety to prevent potential hazards during installation, maintenance, and troubleshooting procedures.

General Safety Guidelines

Always ensure that the equipment is properly grounded before any installation or maintenance work begins. Disconnect all power sources and verify zero voltage before accessing any internal components of the PowerFlex 700S.

Qualified personnel should only perform tasks outlined in this manual, possessing the necessary skills and understanding of AC drive systems. Never attempt modifications or repairs beyond the scope of this documentation.

Read and understand all safety warnings and instructions before operating the drive. Follow all applicable local and national electrical codes. Use appropriate personal protective equipment (PPE) during installation and servicing.

Electrical Safety Warnings

Hazardous voltage exists within the PowerFlex 700S even when the drive is de-energized; capacitors can retain a charge. Always discharge capacitors before touching any internal components. Ensure proper grounding to prevent electric shock.

Never work on energized equipment. Verify complete power disconnection and lockout/tagout procedures are followed. Inspect all wiring for damage before applying power. Avoid contact with live parts.

Qualified personnel must perform all electrical work, adhering to national and local electrical codes. Use insulated tools and wear appropriate PPE. Be aware of potential arc flash hazards.

Mechanical Safety Warnings

Proper mounting is critical for PowerFlex 700S operation. Ensure the drive is securely fastened to a suitable surface capable of supporting its weight. Avoid vibration and shock, which can damage internal components.

Keep the drive enclosure closed during operation to prevent contact with moving parts and to maintain proper cooling. Do not operate a damaged drive. Inspect for loose screws or panels.

Be cautious when handling the drive due to its weight. Use appropriate lifting equipment if necessary. Maintain adequate clearances around the drive for ventilation and servicing.

Understanding the PowerFlex 700S Hardware

PowerFlex 700S hardware includes various frame sizes, control and power wiring terminals, and a robust design for industrial applications.

Understanding these components is vital for correct installation and safe, efficient operation of the AC drive.

Drive Frame Sizes and Dimensions

The PowerFlex 700S is available in multiple frame sizes, specifically Frame 13, and others ranging from 1 through 6, catering to diverse application needs.

These frames dictate the drive’s physical dimensions and power handling capabilities. Detailed dimensional drawings are available in the Appendix for precise mounting considerations.

Properly accounting for these dimensions is crucial during installation to ensure adequate space for wiring, cooling, and overall system integration; Refer to the documentation for specific frame size details.

Selecting the appropriate frame size is essential for optimal performance and longevity of the drive within your application.

Control Wiring Terminals

The PowerFlex 700S utilizes dedicated control wiring terminals for interfacing with external devices. These terminals facilitate communication for start/stop commands, speed references, and feedback signals.

Proper connection to these terminals is vital for seamless integration with PLCs, HMIs, and other automation components. Refer to detailed wiring diagrams in the Appendix for specific terminal assignments.

Careful attention to wiring practices, including correct signal polarity and shielding, is crucial for reliable control and minimizing electrical noise interference.

Incorrect wiring can lead to unpredictable drive behavior or even damage.

Power Wiring Terminals

The PowerFlex 700S features robust power wiring terminals designed to handle substantial voltage and current levels. These terminals are specifically designated for connecting the drive to the main AC power source.

Correctly identifying and utilizing these terminals is paramount for safe and reliable operation. Always adhere to local electrical codes and regulations during installation.

Securely tighten all connections to prevent overheating and ensure proper electrical conductivity. Refer to the Appendix for detailed wiring diagrams and recommended wire gauge specifications.

Improper power wiring can result in severe damage or pose a safety hazard.

Installation Procedures

Proper installation involves unpacking, inspection, mounting, and establishing secure power and control wiring connections. Follow all guidelines for safe operation.

Refer to detailed instructions and diagrams within this manual for a successful PowerFlex 700S setup.

Unpacking and Inspection

Upon receiving the PowerFlex 700S, carefully inspect the shipping container for any signs of damage during transit. Document any external damage immediately with the carrier.

Once opened, verify that the drive matches the ordered specifications, including frame size and voltage rating. Check the included documentation against the packing list to ensure all components are present.

Thoroughly examine the drive for any visible damage, such as loose components, bent fins, or damaged terminals; If damage is detected, do not attempt to install or operate the drive; contact Rockwell Automation support for assistance and guidance.

Mounting the Drive

Proper mounting is crucial for optimal PowerFlex 700S performance and longevity. Select a clean, dry location with adequate ventilation, avoiding direct sunlight and excessive dust.

Ensure the mounting surface is rigid and capable of supporting the drive’s weight. Use appropriate mounting hardware, adhering to specified torque values. Maintain adequate spacing around the drive for airflow and servicing.

Verify secure attachment, preventing vibration or movement. Incorrect mounting can lead to overheating, component failure, and void the warranty. Refer to the drive dimensions drawings in the appendix for detailed mounting guidelines.

Power Connections

Critical safety precautions must be observed during PowerFlex 700S power connections. Always disconnect and lock out main power before commencing any wiring. Verify proper grounding to prevent electrical shock and equipment damage;

Utilize appropriately sized conductors, adhering to local and national electrical codes. Ensure secure connections to prevent overheating and voltage drops. Double-check wiring against approved diagrams before energizing the drive.

Incorrect power connections can result in severe damage and pose a significant safety hazard. Refer to the wiring diagrams in the appendix for detailed instructions.

Control Wiring Connections

Carefully connect control wiring, referencing the appropriate wiring diagrams. Ensure proper termination of all control signals, including start/stop, speed reference, and feedback devices. Shielded cables are recommended to minimize noise interference and maintain signal integrity.

Verify correct polarity and secure connections to prevent erratic operation or damage to the PowerFlex 700S. Double-check all connections before applying power. Incorrect wiring can lead to unexpected behavior.

Consult the manual for specific terminal assignments and configuration requirements for your application.

Parameter Configuration

Accessing drive parameters is key to tailoring the PowerFlex 700S. Configure motor, application, and advanced settings for optimal performance and control.

Proper parameterization ensures the drive operates efficiently and safely within your specific application requirements.

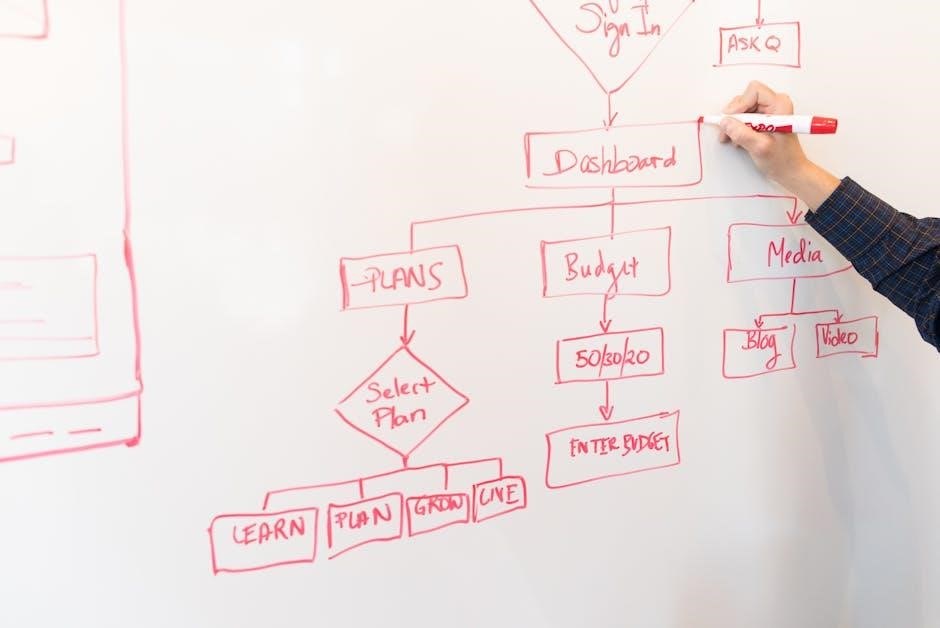

Accessing the Drive Parameters

The PowerFlex 700S offers multiple methods for accessing and modifying its extensive parameter set. Utilizing the integrated Human Interface Module (HIM) provides a direct, menu-driven interface for navigating parameters. Alternatively, communication networks like EtherNet/IP, DeviceNet, or ControlNet enable remote access and control via a computer or programmable logic controller (PLC).

Software packages, such as Rockwell Automation’s Studio 5000, facilitate parameter configuration and monitoring. Understanding the specific communication protocol and associated software is essential for successful remote access. Always refer to the relevant communication protocol manual for detailed setup instructions and troubleshooting guidance.

Motor Parameters Configuration

Accurate motor parameter configuration is vital for optimal PowerFlex 700S performance and protection. Key parameters include motor voltage, full load amps, frequency, and speed. The drive utilizes this data to calculate motor slip and implement appropriate control strategies. Incorrect settings can lead to instability, reduced efficiency, or even motor damage.

Motor nameplate information serves as the primary source for these parameters. Carefully enter these values via the HIM or communication network. Auto-tuning features may assist in refining these settings, but initial accuracy is crucial for reliable operation.

Application Parameters Configuration

Application parameters tailor the PowerFlex 700S to specific process requirements. These settings define how the drive responds to commands and interacts with the driven load. Key configurations include acceleration/deceleration rates, speed references, and operating modes – such as speed control or torque control.

Properly adjusting these parameters optimizes performance for applications like conveyors, pumps, or fans. Consider the mechanical characteristics of the load and desired dynamic response when configuring these settings. Fine-tuning is often necessary to achieve optimal results.

Advanced Parameters Configuration

Advanced parameters within the PowerFlex 700S offer granular control for experienced users. These settings impact drive behavior in complex scenarios, including fault handling, protection thresholds, and communication protocols. Modifying these requires a thorough understanding of drive operation.

Adjustments can optimize performance, but incorrect settings may lead to instability or unintended consequences. Careful consideration and documentation are essential before altering advanced parameters. Refer to the Rockwell Automation documentation for detailed explanations of each setting’s function.

Drive Operation

Starting and stopping the PowerFlex 700S involves understanding speed control modes and ramp configurations for smooth acceleration and deceleration.

Proper setup ensures optimal performance and prevents mechanical stress on connected equipment during operation.

Starting and Stopping the Drive

Initiating drive operation with the PowerFlex 700S requires careful consideration of configured parameters and safety protocols. The drive can be started via external signals, the HMI, or network commands, depending on the application setup.

Stopping the drive offers multiple options, including controlled stops (ramped deceleration) and quick stops for emergency situations. Understanding these modes is vital for preventing damage to the motor and driven load. Proper configuration of stop parameters ensures a safe and controlled shutdown sequence.

Always verify appropriate safety interlocks are active before initiating drive operation, and monitor drive status indicators during startup and shutdown.

Speed Control Modes

The PowerFlex 700S supports various speed control modes to accommodate diverse application requirements. Scalar control (V/Hz) provides simple, cost-effective speed regulation for general-purpose applications. Vector control, offering enhanced performance, delivers precise speed and torque control, ideal for demanding tasks.

Sensorless vector control eliminates the need for an encoder, reducing cost and complexity. Encoder feedback further enhances accuracy and dynamic response. Selecting the appropriate mode depends on the application’s performance needs and budget constraints.

Parameter configuration dictates the chosen speed control method.

Ramp Configuration

The PowerFlex 700S allows precise control over acceleration and deceleration rates through ramp configuration. Acceleration time determines how quickly the drive increases motor speed, while deceleration time controls the slowing down process. These parameters minimize mechanical stress and ensure smooth operation.

S-curve ramps provide a more gradual start and stop, reducing jerk and improving system stability. Linear ramps offer a constant rate of change. Configuring these ramps appropriately optimizes performance and extends equipment lifespan.

Parameter adjustments enable tailored ramp profiles.

Troubleshooting

The PowerFlex 700S offers diagnostic tools, including fault codes and status indicators, to quickly identify and resolve operational issues. Addressing communication problems is also key.

Refer to detailed solutions for common fault codes to minimize downtime and ensure efficient drive performance.

Common Fault Codes and Solutions

Fault Code 1: Overcurrent – Indicates excessive motor current. Verify motor wiring, check for mechanical load issues, and confirm proper drive parameters. Reduce the motor current limit if necessary.

Fault Code 2: Overvoltage – Signals a voltage exceeding the drive’s limit. Inspect input power supply, check for voltage spikes, and ensure proper grounding. Consider using a line reactor.

Fault Code 3: Undervoltage – Indicates insufficient input voltage. Verify power supply voltage, check for loose connections, and ensure adequate cable sizing.

Fault Code 4: Motor Phase Loss – Suggests a missing motor phase. Inspect motor wiring, check for broken conductors, and verify motor connections at the drive.

Fault Code 5: Drive Overload – Indicates the drive is exceeding its thermal capacity. Reduce load, improve ventilation, or consider a larger drive frame size.

Drive Status Indicators

The Drive Ready LED illuminates when the control circuit is energized and the drive is prepared for operation. A Fault LED indicates an active fault condition, requiring investigation and resolution before restarting.

The Run LED signals that the drive is actively controlling the motor. The Terminate LED indicates a commanded stop or fault-induced termination of motor operation.

The Frequency Reference indicator displays the current output frequency. The Current Limit indicator shows when the drive is operating at its current limit.

The DC Bus Voltage indicator provides a visual representation of the DC bus voltage level. Monitoring these indicators aids in diagnosing drive status and potential issues.

Communication Issues

Communication failures can stem from incorrect network configurations, damaged cabling, or incompatible communication protocols. Verify proper IP address settings for EtherNet/IP, and confirm DeviceNet or ControlNet network integrity.

Check physical connections, ensuring secure terminations and cable shielding. Confirm baud rates and communication parameters match between the drive and the controlling device.

Diagnostic tools within the drive can assist in identifying communication errors. Review the drive’s fault log for specific communication-related fault codes.

Restarting the drive and the communication device can sometimes resolve temporary communication glitches. Consult network documentation for troubleshooting guidance.

Communication Protocols

The PowerFlex 700S supports multiple communication protocols, including EtherNet/IP, DeviceNet, and ControlNet, enabling seamless integration with industrial systems.

Configuration details for each protocol are essential for establishing reliable communication between the drive and other network devices.

EtherNet/IP Configuration

EtherNet/IP configuration for the PowerFlex 700S involves assigning a static IP address, subnet mask, and gateway, ensuring proper network connectivity. Utilize Rockwell Automation’s Studio 5000 software for streamlined setup and parameterization.

Verify network settings and confirm communication by pinging the drive from a connected computer; Proper configuration enables advanced features like remote monitoring, control, and data logging. Ensure the drive’s EDS file is imported into Studio 5000 for seamless integration and access to drive parameters.

Troubleshooting network issues often involves checking cable connections and verifying IP address conflicts.

DeviceNet Configuration

DeviceNet configuration on the PowerFlex 700S requires a compatible DeviceNet adapter and appropriate cabling. Utilize Rockwell Automation’s RSNetWorx for DeviceNet software to establish communication parameters.

Assign a unique node address to the drive within the DeviceNet network, ensuring no address conflicts exist. Import the drive’s EDS (Electronic Data Sheet) file into RSNetWorx to define device attributes and messaging capabilities. Verify proper network termination and baud rate settings for reliable data exchange.

Troubleshooting involves checking wiring and EDS file integrity.

ControlNet Configuration

ControlNet setup for the PowerFlex 700S necessitates a ControlNet interface module and correct network topology. Employ Rockwell Automation’s ControlNet Configuration Tool to define network parameters and device attributes.

Assign a unique node address to the drive, avoiding duplicates within the ControlNet network. Import the drive’s EDS file to define messaging and data exchange capabilities. Confirm proper network termination and baud rate settings for stable communication.

Diagnostic tools within the configuration software aid in troubleshooting connectivity issues.

Drive Protection Features

The PowerFlex 700S incorporates robust protection, including overload, overvoltage, and undervoltage safeguards. These features enhance drive reliability and longevity.

These protections prevent damage and ensure safe operation during various fault conditions, extending the lifespan of the drive.

Overload Protection

Overload protection within the PowerFlex 700S is a critical safety feature designed to prevent damage to both the drive and the connected motor. This protection actively monitors the motor current, comparing it against pre-defined limits configured through drive parameters.

When the motor current exceeds these established thresholds for a specified duration, the drive initiates a controlled stop, safeguarding against overheating and potential winding failures. Users can customize overload settings to match the motor’s nameplate data and application requirements, optimizing performance and protection.

Proper configuration ensures reliable operation and extends the lifespan of the motor and drive system.

Overvoltage Protection

Overvoltage protection in the PowerFlex 700S safeguards the drive from damaging voltage spikes or excessive DC bus voltage. This crucial feature continuously monitors the DC bus voltage, triggering a protective response when pre-set limits are surpassed.

Upon detecting an overvoltage condition, the drive initiates a controlled shutdown, preventing potential damage to internal components. Users can configure the overvoltage trip level via drive parameters, tailoring it to the specific application and power supply characteristics.

This proactive protection enhances drive reliability and longevity.

Undervoltage Protection

Undervoltage protection within the PowerFlex 700S is a vital safety mechanism, shielding the drive and connected motor from operation with insufficient supply voltage. The drive constantly monitors the incoming voltage, comparing it against user-defined thresholds.

When the voltage dips below the configured minimum, the drive initiates a controlled stop, preventing potential motor stalling, overheating, and damage to drive components. Adjustable parameters allow customization of the undervoltage trip point.

This feature ensures reliable and safe operation.

Maintenance and Repair

Routine maintenance, including cleaning procedures, is vital for optimal PowerFlex 700S performance. Component replacement should only be performed by qualified personnel.

Regular inspections help ensure longevity and prevent unexpected downtime, maintaining reliable operation of the AC drive system.

Routine Maintenance Tasks

Regular inspections are paramount for maintaining the PowerFlex 700S drive’s reliability. Cleaning procedures should be performed periodically to remove dust and debris, preventing overheating and potential failures.

Visually check wiring connections for tightness and signs of damage. Inspect cooling fans for proper operation, ensuring adequate airflow. Monitor drive temperature and ambient conditions.

Document all maintenance activities and any observed anomalies. Following these tasks proactively extends the drive’s lifespan and minimizes unscheduled downtime, optimizing overall system performance.

Cleaning Procedures

Regular cleaning of the PowerFlex 700S is vital for optimal performance. Disconnect power before initiating any cleaning process to ensure safety. Use compressed air to remove dust and debris from the drive’s internal components and exterior surfaces.

A soft, lint-free cloth dampened with isopropyl alcohol can be used to gently wipe down the enclosure. Avoid using harsh chemicals or abrasive cleaners, as they may damage the drive.

Ensure the drive is completely dry before restoring power. Consistent cleaning prevents overheating and maintains reliable operation.

Replacing Components

Component replacement should only be performed by qualified personnel. Always disconnect power and discharge capacitors before attempting any repairs. Refer to the PowerFlex 700S technical documentation for specific component identification and replacement procedures.

Ensure replacement parts are genuine Rockwell Automation components to maintain drive performance and safety. Carefully follow all installation instructions and torque specifications.

Post-replacement, thoroughly inspect wiring connections and perform functional testing before restoring power to verify correct operation.

Technical Specifications

PowerFlex 700S specifications, including input/output voltage ranges and current ratings, are detailed in the PowerFlex 700 Adjustable Frequency AC Drive Technical Data publication.

Consult this document for precise values based on specific frame sizes and configurations.

Input Voltage Range

The PowerFlex 700S drive accommodates a broad spectrum of input voltages, ensuring compatibility with diverse power systems. Specific voltage ranges are contingent upon the drive’s frame size, with options available for both low and medium voltage applications.

Detailed input voltage specifications, including acceptable minimum and maximum values, are comprehensively documented within the PowerFlex 700 Adjustable Frequency AC Drive Technical Data publication.

Always refer to this publication for precise voltage requirements corresponding to your specific PowerFlex 700S model to guarantee optimal performance and prevent potential damage.

Output Voltage Range

The PowerFlex 700S delivers a versatile output voltage range, adaptable to various motor requirements and application demands. The specific output voltage capabilities are directly linked to the drive’s frame size and configuration.

Detailed output voltage specifications, including nominal and maximum values, are thoroughly outlined in the PowerFlex 700 Adjustable Frequency AC Drive Technical Data publication.

Consult this document to ascertain the precise output voltage range supported by your particular PowerFlex 700S model, ensuring optimal motor performance and system reliability.

Current Ratings

The PowerFlex 700S boasts a wide spectrum of current ratings, meticulously engineered to accommodate diverse motor sizes and load characteristics. These ratings are fundamentally determined by the drive’s frame size, directly influencing its capacity to handle varying current demands.

For precise current rating details – including continuous and peak current limits – refer to the PowerFlex 700 Adjustable Frequency AC Drive Technical Data publication.

This resource provides crucial information for selecting the appropriate drive for your application, guaranteeing optimal performance and preventing potential overload scenarios.

Appendix

This section contains valuable supplementary materials, including detailed drive dimensions drawings, comprehensive wiring diagrams, and essential certification information for the PowerFlex 700S.

Drive Dimensions Drawings

Detailed dimensional drawings are crucial for proper installation and enclosure planning of the PowerFlex 700S. These drawings, found within this appendix, illustrate frame sizes, mounting hole locations, and overall drive footprints.

Accurate measurements ensure sufficient clearance for wiring, cooling, and maintenance access. Refer to these diagrams to verify compatibility with existing or planned control panels and enclosures.

Properly utilizing these drawings minimizes installation errors and maximizes the lifespan of your PowerFlex 700S drive, contributing to reliable system operation and reduced downtime.

Wiring Diagrams

Comprehensive wiring diagrams are essential for safe and correct installation of the PowerFlex 700S drive. These diagrams detail power connections, control wiring, and communication interfaces, ensuring proper functionality.

Carefully follow these diagrams to avoid miswiring, which could damage the drive or connected equipment. Diagrams illustrate terminal assignments for various configurations, including input/output signals.

Referencing these diagrams alongside the installation instructions guarantees a secure and reliable connection, optimizing performance and minimizing potential hazards during commissioning and operation.

Certification Information

The PowerFlex 700S drive adheres to stringent industry standards, ensuring safety and performance. Certification details, previously included in Appendix A, are now located within the dedicated PowerFlex 700 Adjustable Frequency AC Drive Technical Data publication.

This documentation outlines compliance with various regional and international regulations, including those related to electromagnetic compatibility (EMC) and safety standards. Verification of these certifications confirms the drive’s suitability for diverse applications.

Consult the technical data for the most up-to-date and comprehensive certification information.